Core Classification and Technical Features of Welding Workstations

As the core equipment for automated welding, the types of welding workstations are mainly determined by welding processes and application scenarios. Currently, the mainstream classifications in the market include:

1. Box Welding Robot Workstation

Designed specifically for the cabinet industry, it is suitable for welding large - sized workpieces such as electrical control cabinets and air - tight boxes. This workstation adopts a double - station positioner structure, which supports simultaneous welding and workpiece disassembly and assembly operations, with an efficiency increase of over 30%. The core configuration includes a six - axis industrial robot and a MIG/CMT welding system. Through intelligent control, it can achieve weld seam sealability detection, making it particularly suitable for high - precision welding scenarios such as stainless steel.

It uses a fiber laser and a five - axis linkage system, suitable for precision welding of 5G base station metal shells, automobile bodies, etc. The heat - affected zone of laser beam welding is only 1/3 of that of traditional processes, and it supports a plate gap of 0.2 - 0.5mm. With a vision positioning system, it can achieve a repeat positioning accuracy of ±0.1mm.

3. Spot Welding and Arc Welding Composite Workstation

Widely used in the automobile manufacturing field, by integrating a spot welding gun and an arc welding module, it can complete the strength welding and decorative welding of the body frame. Servo drive technology shortens the single - point welding time to 0.3 seconds, with an efficiency increase of over 5 times compared to manual work.

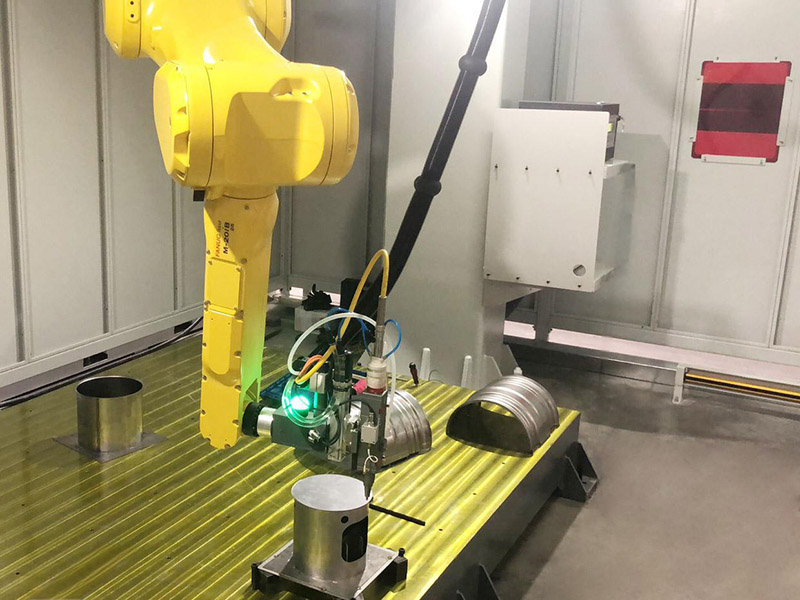

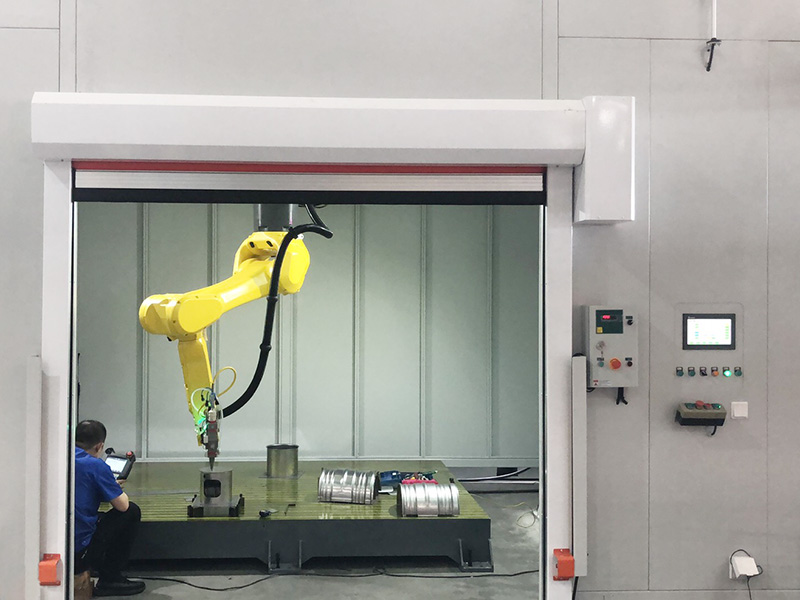

3D laser cutting robotic workstation

Small circle cutting

3D laser cutting in new energy vehicle manufacturing

In - depth Analysis of Price Influencing Factors

The quotes for welding workstations can range from 200,000 to 3 million yuan, mainly depending on the following factors:

- Process System: The cost of laser welding equipment is 60% - 80% higher than that of traditional arc welding. The technical premium of core components such as three - dimensional five - axis laser heads is significant.

- Automation Level: Workstations equipped with a seventh - axis guide rail and visual inspection are 40% - 50% more expensive than basic models.

- Premium of Domestic Brands: The price of imported brands (such as European brands) for the same - specification equipment is usually 1.5 - 2 times that of domestic brands.

- Industry Customization Degree: The double - station system required for sealing box welding can increase the equipment cost by 15% - 20%.

Purchase Strategies and Quality Control Points

Selecting a welding workstation needs to be carried out in four steps:

1. Evaluation of Process Matching Degree: For box - type workpieces, a double - station rotary system is preferred. For thin - plate welding, CMT cold metal transfer technology is recommended.

2. Verification of Supplier Technology: Request the mechanical performance report of welding sample workpieces, and focus on testing the tensile strength and air - tightness of the weld seams.

3. Confirmation of System Expandability: Confirm whether the workstation supports the installation of intelligent modules such as weld seam tracking and quality monitoring.

4. Test of After - sales Response Ability: Assess the spare parts inventory rate of the manufacturer and the response speed of the remote diagnostic system.

Industry data shows that using a standard welding workstation can reduce the enterprise's welding cost by 28% and increase the non - defective rate to over 98.5%. It is recommended to conduct on - site welding tests and comparisons among at least three manufacturers before purchase, and focus on the stability performance of the equipment after continuous operation for 8 hours.